Why MOFs Matter: The Supermaterials Changing Energy, Medicine, and the Planet

Abstract

Metal–organic frameworks (MOFs) are a class of porous crystalline materials constructed from metal ions and organic linkers. This blog explores their fundamental structure and highlights their broad applications across five key domains: gas storage and separation, catalysis and energy systems, biomedical technologies, and environmental remediation. The article also examines current challenges in MOF research—such as stability, scalability, and device integration—and outlines future directions, including AI-assisted design and smart MOF development. With their modularity, tunability, and exceptional surface area, MOFs are emerging as transformative materials poised to impact energy, health, and environmental sustainability on a global scale.

Introduction to Metal–Organic Frameworks (MOFs)

Metal–Organic Frameworks, commonly known as MOFs, are an extraordinary class of crystalline materials composed of metal ions or clusters coordinated to organic ligands. These two components link together to form porous, lattice-like structures with extremely high surface areas — often exceeding 5,000 m²/g. Since their discovery in the late 1990s, MOFs have captured the attention of scientists across disciplines, from chemistry and materials science to environmental engineering and biomedicine.

What makes MOFs particularly remarkable is their structural tunability. By simply altering the metal center or the organic linker, researchers can design MOFs with specific pore sizes, shapes, and functionalities. This level of control enables MOFs to serve as highly customizable platforms for a broad range of applications, including gas storage, catalysis, drug delivery, and energy storage.

Another notable feature of MOFs is their modularity. Unlike traditional porous materials like zeolites or activated carbon, MOFs can be systematically engineered at the molecular level. This makes them ideal candidates for precision applications, such as selective gas separation or responsive drug delivery systems. Furthermore, advances in synthetic chemistry have allowed for the production of water-stable and biocompatible MOFs, expanding their utility in real-world conditions.

Today, MOFs are seen not just as laboratory curiosities but as key players in addressing some of the world’s most pressing challenges—such as climate change, clean energy, and sustainable healthcare. As research continues, MOFs are expected to move from niche materials to industrial-scale solutions with transformative impacts.

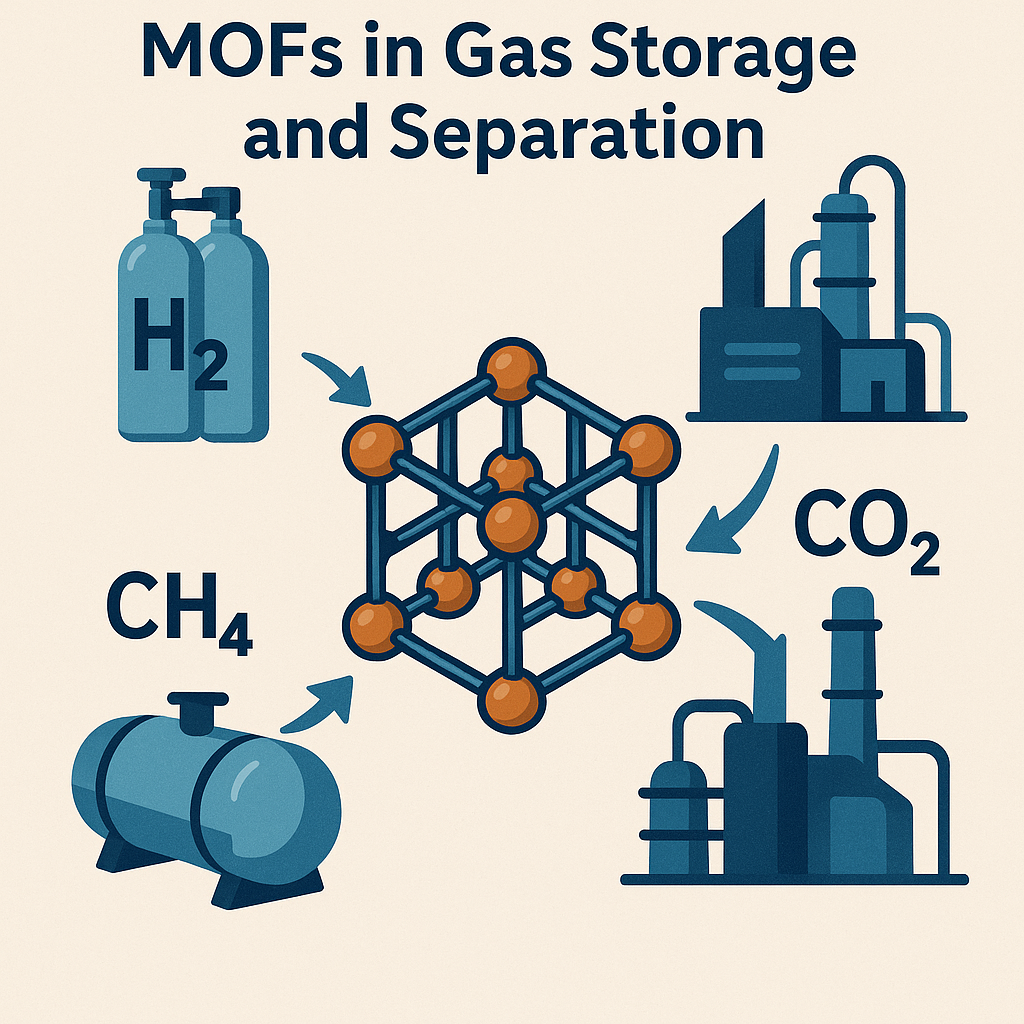

MOFs in Gas Storage and Separation

One of the most compelling applications of metal–organic frameworks (MOFs) lies in gas storage and separation, where their high porosity and tunable pore environments provide significant advantages over traditional adsorbents. Their internal surface areas can reach over 7,000 m²/g, making them highly effective for capturing and storing various gases — from energy carriers like hydrogen (H₂) and methane (CH₄) to greenhouse gases like carbon dioxide (CO₂).

Gas Storage:

MOFs can store gases at lower pressures and ambient temperatures, addressing safety and efficiency challenges. For instance, hydrogen storage is a major hurdle in advancing hydrogen fuel cell technologies. MOFs like MOF-5, HKUST-1, and MIL-101 have demonstrated exceptional hydrogen uptake capabilities due to their large pores and active sites. Similarly, MOFs are being tested as alternatives to compressed natural gas (CNG) tanks for safer and denser methane storage.

Gas Separation:

Thanks to their well-defined pore sizes and functional groups, MOFs exhibit selective adsorption properties. This enables them to distinguish between gas molecules with similar sizes or properties — a crucial requirement in industrial gas purification. For example:

CO₂/N₂ separation in carbon capture technologies

Ethylene/ethane (C₂H₄/C₂H₆) separation for petrochemical processing

O₂/N₂ separation in air enrichment systems

By tailoring the linker chemistry and incorporating open metal sites, researchers have designed MOFs that not only trap specific gases efficiently but also release them reversibly, making them reusable and cost-effective.

As global attention intensifies around climate change and clean energy, MOFs are increasingly seen as strategic materials for reducing emissions and storing alternative fuels. Their ability to outperform traditional materials is transforming how we think about gas handling in both environmental and industrial contexts.

MOFs in Catalysis and Energy Applications

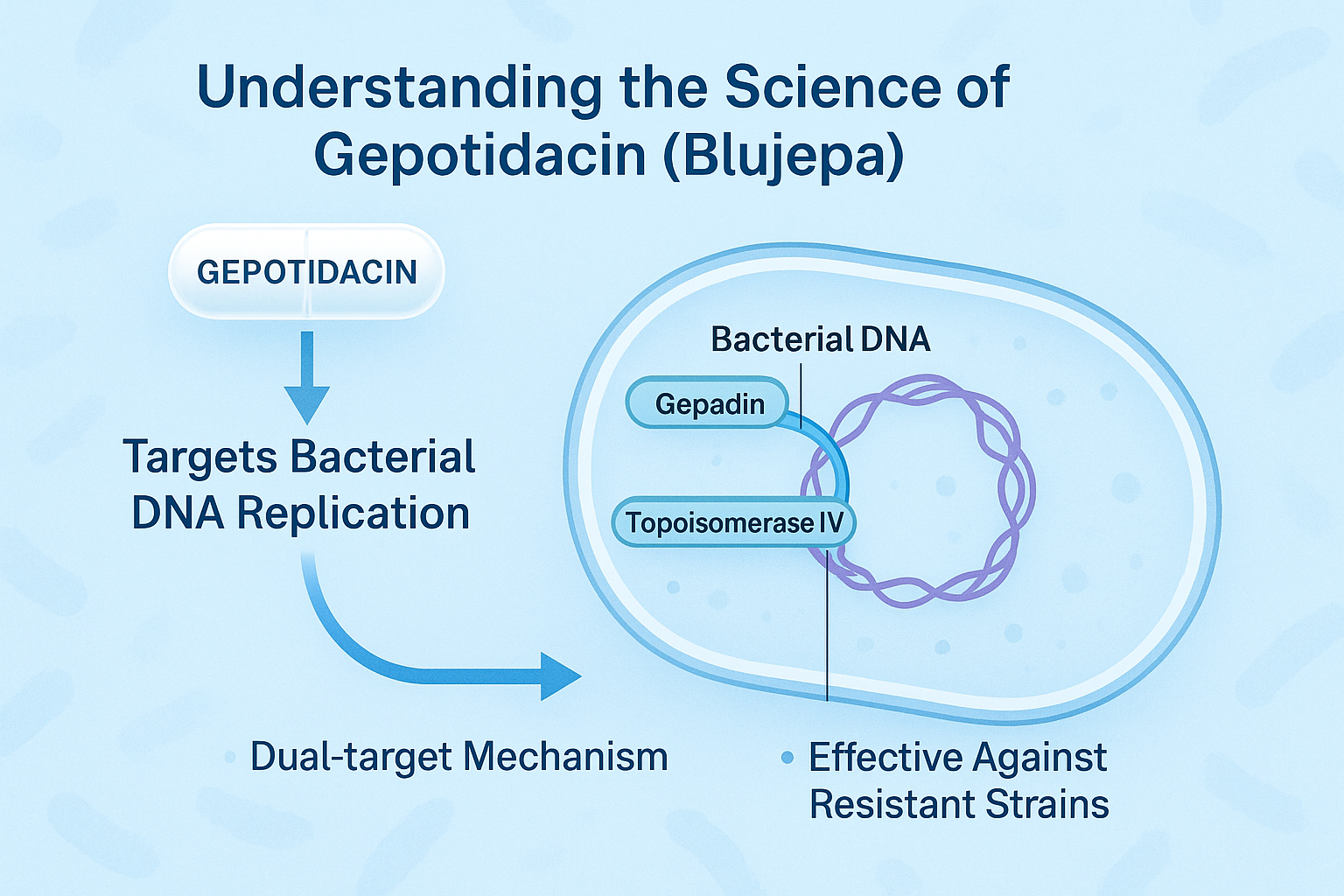

Beyond their role in gas storage, metal–organic frameworks (MOFs) have proven to be highly versatile materials in catalysis and energy conversion and storage. Thanks to their hybrid organic-inorganic nature and customizable architecture, MOFs can mimic the active sites of enzymes or function as tailored microreactors.

Catalysis:

MOFs act as both heterogeneous and homogeneous catalysts, depending on their design. Their internal surfaces can house Lewis acidic metal sites, Brønsted acids, or functionalized linkers, enabling a wide range of chemical reactions:

Oxidation and reduction reactions (e.g., alcohol oxidation, olefin epoxidation)

CO₂ conversion into valuable chemicals

Photocatalytic reactions, using MOFs like Ti-based MIL-125 to harvest light for green chemistry processes

Some MOFs are also being engineered as enzyme mimics, capable of catalyzing biochemical reactions under mild conditions. Their well-ordered porosity ensures that reactants and products can efficiently diffuse to and from active sites.

Energy Storage and Conversion:

MOFs and their derivatives have become attractive for next-generation energy technologies:

Battery materials: MOFs can be converted into porous carbon composites with embedded metal nanoparticles, which function as electrodes in lithium-ion, sodium-ion, and zinc-ion batteries.

Supercapacitors: The high surface area and tunable conductivity of MOF-derived materials allow for efficient ion adsorption and rapid charge-discharge cycles.

Hydrogen evolution reaction (HER) and oxygen reduction reaction (ORR): MOFs with catalytically active metal sites (e.g., Fe, Co, Ni) are being used as electrocatalysts in water splitting and fuel cells.

These applications place MOFs at the intersection of green chemistry, renewable energy, and nanotechnology—positioning them as materials of the future in the shift toward sustainable and efficient energy systems.

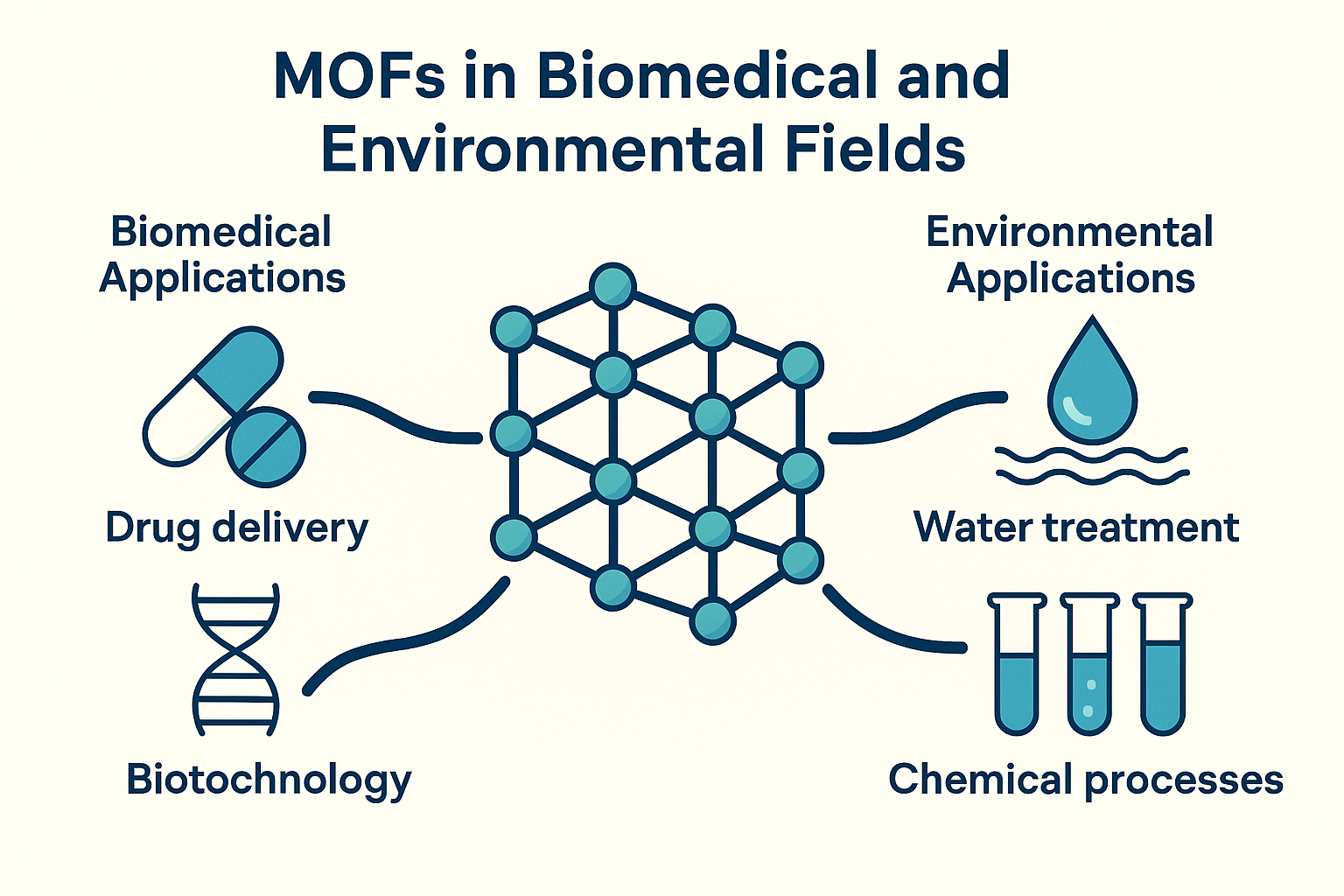

MOFs in Biomedical and Environmental Fields

As researchers continue to uncover the versatility of metal–organic frameworks (MOFs), their applications have extended into critical areas such as biomedicine and environmental remediation. The same characteristics that make MOFs exceptional for gas storage and catalysis—such as tunable pore size, high surface area, and modular functionality—also enable their success in these socially impactful fields.

Biomedical Applications:

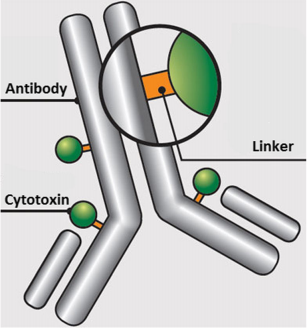

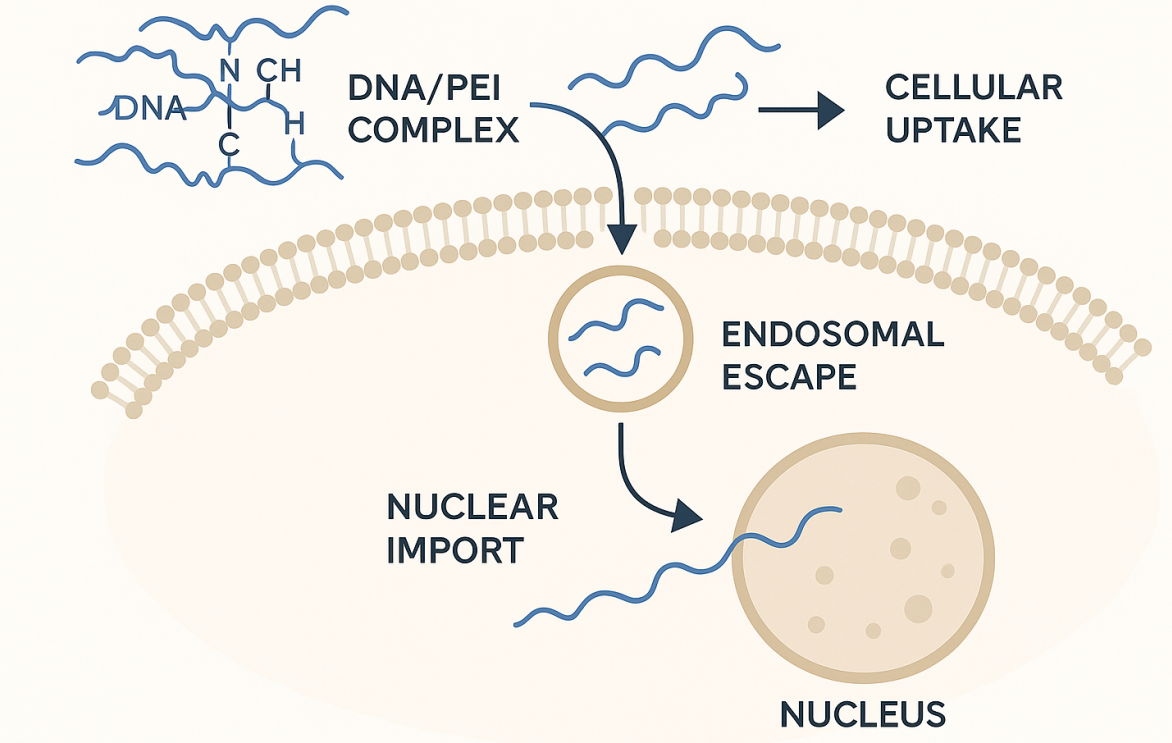

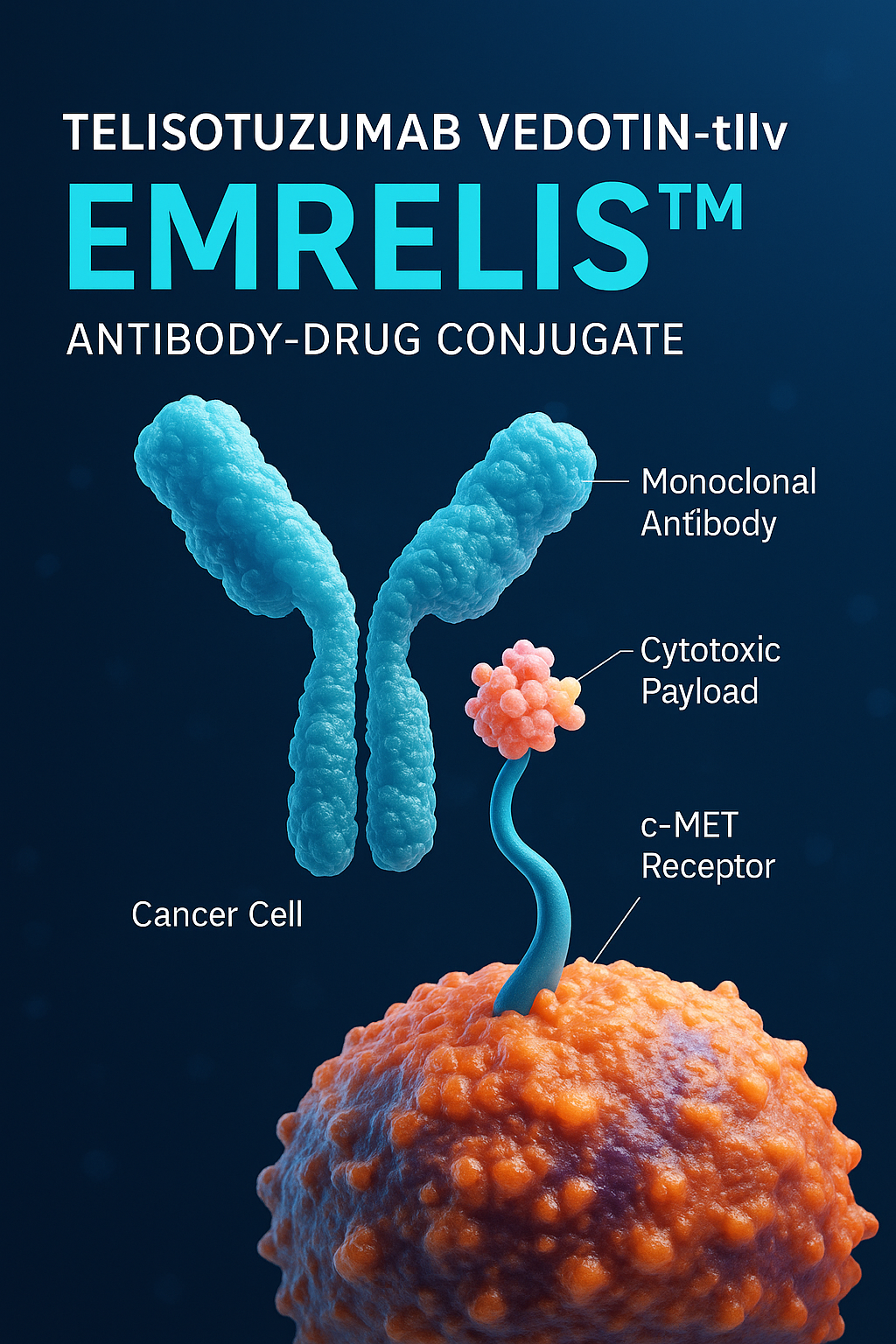

MOFs have emerged as promising candidates for drug delivery, biosensing, and bioimaging. Their porous structure allows for the encapsulation of a variety of therapeutic agents, from small-molecule drugs to large biomolecules like DNA.

Targeted drug delivery: MOFs like ZIF-8 and MIL-100(Fe) respond to environmental stimuli such as pH, releasing their drug payload in acidic environments (e.g., tumors).

Imaging and diagnostics: Functionalized MOFs can be loaded with contrast agents or fluorescent tags for real-time tracking and imaging of biological processes.

Biocompatibility and biodegradability: With proper selection of metal centers (e.g., Fe, Zn) and linkers, MOFs can be made safe for use in vivo, and even degradable under physiological conditions.

Environmental Applications:

In the fight against pollution and climate change, MOFs offer groundbreaking tools for environmental cleanup:

Heavy metal adsorption: MOFs can selectively adsorb toxic ions like Pb²⁺, Hg²⁺, and Cr⁶⁺ from wastewater through chelation or ion exchange.

Organic pollutant removal: Their large internal surface allows efficient capture and photodegradation of dyes, antibiotics, and pesticides.

Photocatalytic degradation: MOFs like Ti-based MIL-125 and NH₂-UiO-66 can harness light to degrade pollutants under mild conditions.

By addressing both healthcare and environmental crises, MOFs stand as multifunctional materials with real-world transformative potential.

Challenges and Future Outlook for MOFs

While metal–organic frameworks (MOFs) have shown immense promise across a range of scientific and industrial domains, several critical challenges must be addressed before they can be widely commercialized. However, these hurdles are equally matched by exciting future opportunities that could define the next generation of smart materials.

Current Challenges:

Stability Issues

Many MOFs suffer from poor water and thermal stability, especially those with labile metal-ligand bonds. This limits their real-world applicability in humid or high-temperature environments. Researchers are actively developing more robust MOFs, such as those based on Zr or Al, to overcome this limitation.

Scalability and Cost

MOFs are typically synthesized under solvothermal conditions using expensive solvents and linkers. Producing them in large volumes, with consistent quality, remains economically challenging. Greener, solvent-free or continuous flow synthesis methods are being explored as alternatives.

Integration into Devices

Translating MOFs from powder form to functional devices—such as membranes, electrodes, or sensors—requires innovations in materials processing, shaping, and coating techniques.

Limited Conductivity

For electronic and energy applications, most MOFs are electrically insulating. Conductive MOFs or MOF-derived composites are a growing subfield, but challenges in preserving framework integrity during processing remain.

Future Directions:

AI-Assisted MOF Design

With thousands of known MOF structures and even more possible combinations, machine learning and computational modeling are being used to predict optimal frameworks for specific tasks.

Stimuli-Responsive (Smart) MOFs

MOFs that respond to pH, light, heat, or specific chemicals could revolutionize fields like targeted drug delivery, environmental sensing, and self-healing materials.

Green and Circular MOFs

Emphasis is growing on sustainable synthesis, recyclable frameworks, and bio-based linkers for MOFs with minimal environmental footprint.

Industrial Deployment

Areas like carbon capture, clean hydrogen storage, and selective gas separation are already seeing pilot-scale testing, signaling the dawn of MOF-based industrial applications.

In summary, MOFs are no longer just laboratory curiosities—they are well on their way to becoming core materials in the toolkit of chemists, engineers, and technologists tackling some of humanity’s greatest challenges.

References

Furukawa, H., Cordova, K. E., O’Keeffe, M., & Yaghi, O. M. (2013). The chemistry and applications of metal–organic frameworks. Science, 341(6149), 1230444.

https://www.science.org/doi/abs/10.1126/science.1230444

Yaghi, O. M., O’Keeffe, M., Ockwig, N. W., Chae, H. K., Eddaoudi, M., & Kim, J. (2003). Reticular synthesis and the design of new materials. Nature, 423(6941), 705–714.

https://www.nature.com/articles/nature01650

Li, J.-R., Kuppler, R. J., & Zhou, H.-C. (2009). Selective gas adsorption and separation in metal–organic frameworks. Chemical Society Reviews, 38(5), 1477–1504.

https://pubs.rsc.org/en/content/articlelanding/2009/cs/b802426j/unauth

Kitagawa, S., Kitaura, R., & Noro, S. (2004). Functional porous coordination polymers. Angewandte Chemie International Edition, 43(18), 2334–2375.

https://onlinelibrary.wiley.com/doi/abs/10.1002/anie.200300610

Sumida, K., Rogow, D. L., Mason, J. A., McDonald, T. M., Bloch, E. D., Herm, Z. R., … & Long, J. R. (2012). Carbon dioxide capture in metal–organic frameworks. Chemical Reviews, 112(2), 724–781.

https://pubs.acs.org/doi/full/10.1021/cr2003272

Bae, Y.-S., & Snurr, R. Q. (2011). Development and evaluation of porous materials for carbon dioxide separation and capture. Angewandte Chemie International Edition, 50(49), 11586–11596.

https://onlinelibrary.wiley.com/doi/abs/10.1002/anie.201101891

Mason, J. A., Veenstra, M., & Long, J. R. (2014). Evaluating metal–organic frameworks for natural gas storage. Chemical Science, 5(1), 32–51.

https://pubs.rsc.org/en/content/articlehtml/2014/sc/c3sc52633j

Wang, Q., Astruc, D. (2017). State of the art and prospects in metal–organic framework (MOF)-based and MOF-derived nanocatalysis. Chemical Reviews, 120(3), 1438–1511.

https://pubs.acs.org/doi/abs/10.1021/acs.chemrev.9b00223

Xie, L. S., Skorupskii, G., & Dincă, M. (2020). Electrically conductive metal–organic frameworks. Chemical Reviews, 120(16), 8536–8580.

https://pubs.acs.org/doi/full/10.1021/acs.chemrev.9b00766

Horcajada, P., Chalati, T., Serre, C., Gillet, B., Sebrie, C., Baati, T., … & Férey, G. (2010). Porous metal–organic-framework nanoscale carriers as a potential platform for drug delivery and imaging. Nature Materials, 9(2), 172–178.

https://www.nature.com/articles/nmat2608

Wu, M. X., & Yang, Y. W. (2017). Metal–organic framework (MOF)-based drug/cargo delivery and cancer therapy. Advanced Materials, 29(23), 1606134.

https://advanced.onlinelibrary.wiley.com/doi/abs/10.1002/adma.201606134

Wang, H., Zhu, Q. L., Zou, R., & Xu, Q. (2017). Metal–organic frameworks for energy applications. Chemical, 2(1), 52–80.

https://www.cell.com/chem/fulltext/S2451-9294(16)30267-4

Burtch, N. C., Jasuja, H., & Walton, K. S. (2014). Water stability and adsorption in metal–organic frameworks. Chemical Reviews, 114(20), 10575–10612.

https://pubs.acs.org/doi/full/10.1021/cr5002589

Moosavi, S. M., Jablonka, K. M., & Smit, B. (2020). The role of machine learning in the understanding and design of materials. Journal of the American Chemical Society, 142(48), 20273–20287.