OLED Materials: Driving the Future of Flexible, Efficient, and Sustainable Displays

Abstract

Organic Light Emitting Diodes (OLEDs) have revolutionized modern display and lighting technologies by enabling high-efficiency, flexible, and ultra-thin devices. This blog explores the fundamental OLED material components—emissive, transport, and injection layers—and how their performance drives device quality. It also highlights recent advances such as TADF emitters, printable OLEDs, and sustainable synthesis methods. Key applications include smartphones, automotive lighting, wearables, and emerging AR/VR displays. Despite challenges like blue emitter stability, manufacturing cost, and energy efficiency, continuous innovation in OLED materials promises a sustainable and scalable future. As the industry evolves, OLEDs are set to play a pivotal role in next-generation electronics, offering unique solutions in both consumer and industrial sectors.

What Are OLED Materials?

Organic Light Emitting Diodes (OLEDs) are a class of display and lighting technologies that use organic compounds to emit light in response to an electric current. Unlike traditional LEDs, which rely on inorganic semiconductors, OLEDs are based on carbon-containing materials that offer unique advantages, including high contrast ratios, vibrant colors, ultra-thin designs, and the ability to create flexible and transparent displays.

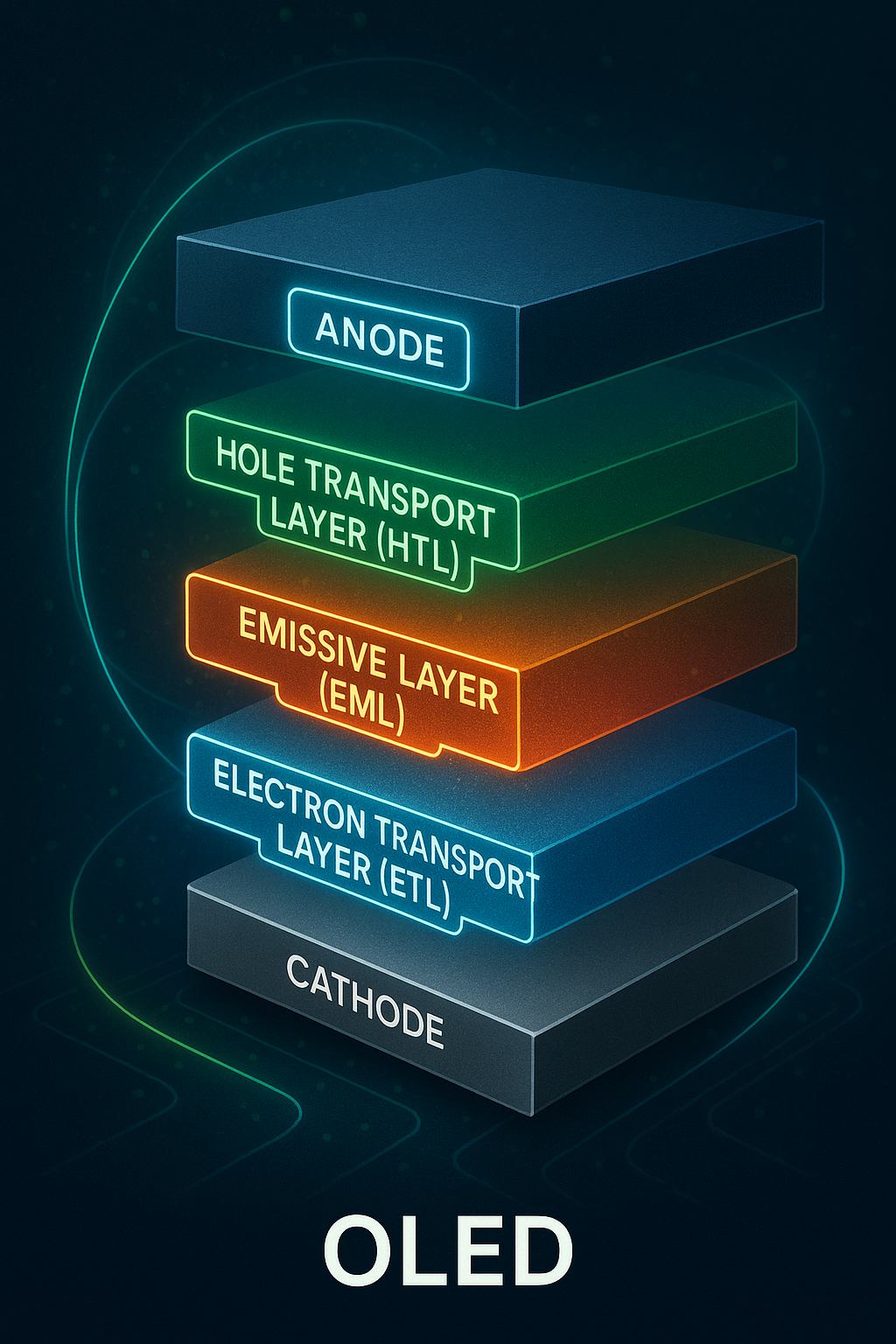

At the heart of every OLED device are specially engineered materials organized in multilayer structures. These materials are responsible for key processes such as charge injection, charge transport, and electroluminescence. OLED materials are generally divided into several functional layers: the anode, hole transport layer (HTL), emissive layer (EML), electron transport layer (ETL), and cathode. The emissive layer is where organic compounds emit light when excited by the recombination of electrons and holes.

OLED materials fall into several categories depending on their function. Emissive materials can be fluorescent or phosphorescent, each offering different levels of efficiency and color quality. Charge transport and injection materials facilitate the movement of holes and electrons to the emissive layer. Material performance—including energy efficiency, stability, and color purity—plays a pivotal role in determining the overall quality of an OLED display or lighting panel.

Due to their inherent properties, OLED materials are central to innovations in next-generation consumer electronics, including smartphones, televisions, and wearable devices. As research progresses, new materials such as thermally activated delayed fluorescence (TADF) compounds and hybrid perovskite-based materials continue to expand the potential of OLED technologies.

The Core Components of OLED Materials

The performance of an OLED display or lighting system is heavily influenced by the quality and functionality of its core components. These components work together in a layered structure to efficiently produce light and achieve the desired visual effects. The primary layers in an OLED device include the anode, hole transport layer (HTL), emissive layer (EML), electron transport layer (ETL), and cathode. Each of these layers is composed of specific materials that serve distinct functions.

Emissive Materials: The emissive layer is where light is generated in an OLED. It consists of organic molecules that emit light when excited by an electric current. These materials can be fluorescent or phosphorescent, with phosphorescent materials being more efficient as they can utilize both singlet and triplet excitons to produce light. The choice of emissive material directly affects the color and brightness of the emitted light.

Hole Transport Materials (HTMs): The HTM is responsible for transporting positive charge carriers (holes) from the anode to the emissive layer. These materials are essential for efficient charge injection and transport, ensuring that the OLED operates effectively. Materials with high hole mobility are preferred to minimize energy losses and enhance performance.

Electron Transport Materials (ETMs): ETMs carry electrons from the cathode to the emissive layer. Like HTMs, ETMs play a critical role in ensuring that the OLED device maintains balanced charge injection and efficient light emission. These materials are typically chosen for their ability to provide fast electron transport without compromising the device’s overall stability.

Charge Injection Materials: Charge injection layers help in the efficient injection of holes and electrons from the anode and cathode, respectively. These materials optimize the performance by ensuring that both charge carriers are delivered to the emissive layer efficiently, which is crucial for high-efficiency OLED displays and lighting devices.

By fine-tuning these components, researchers and manufacturers can improve OLED efficiency, color accuracy, and lifespan, driving the continued evolution of OLED technology in applications ranging from televisions to flexible displays and even lighting systems.

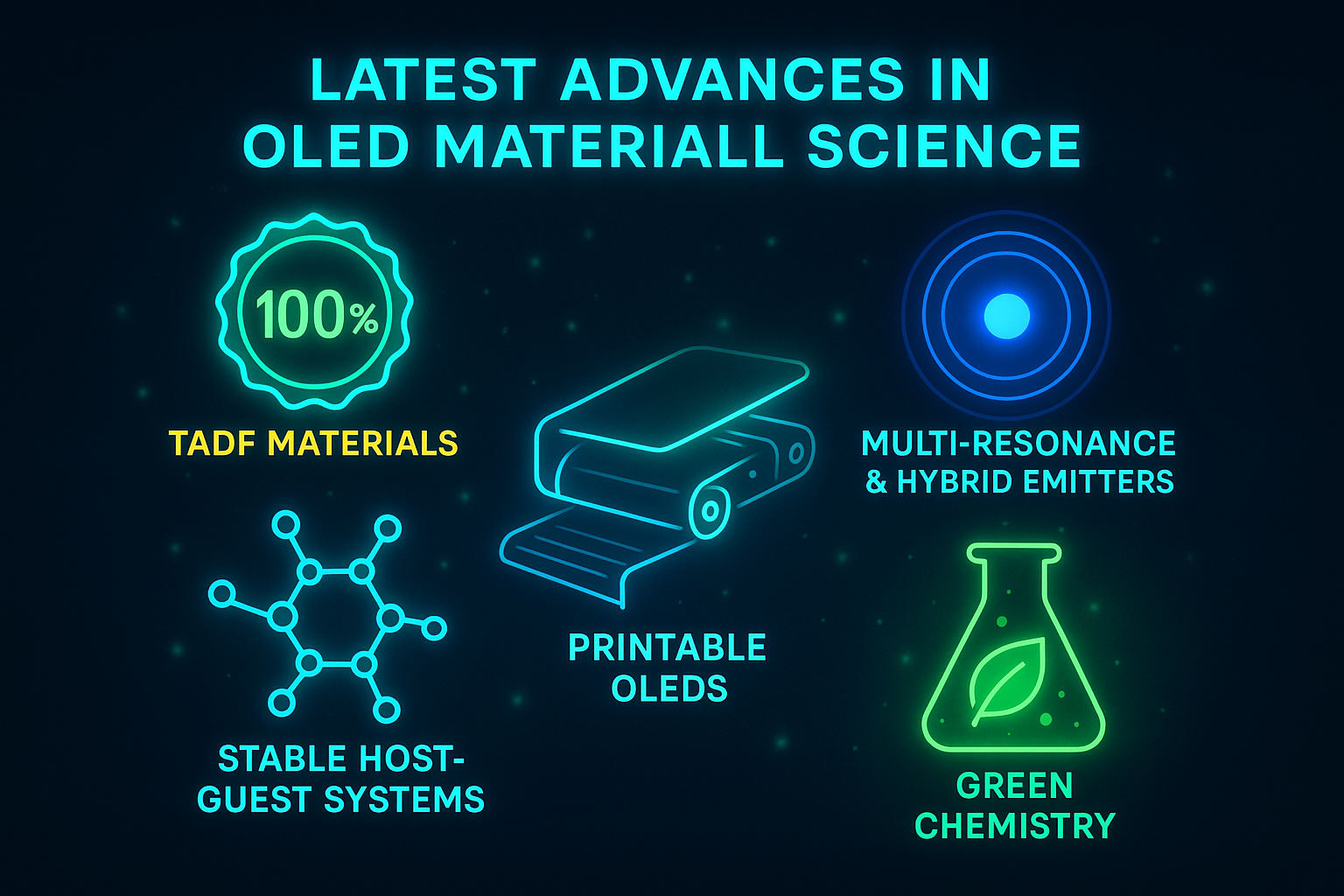

Latest Advances in OLED Material Science

The field of OLED materials has seen rapid advancements driven by the demand for more energy-efficient, vibrant, and longer-lasting displays. Among the most significant developments is the rise of thermally activated delayed fluorescence (TADF) materials. These compounds offer near 100% internal quantum efficiency by harvesting both singlet and triplet excitons for light emission—similar to phosphorescent materials but without the need for rare and costly heavy metals like iridium.

In addition to TADF, researchers are exploring multi-resonance emitters and hybrid fluorescent–phosphorescent systems to achieve sharper emission spectra and better stability. These innovations have helped produce OLEDs with improved color purity, especially for challenging hues like deep blue, which has historically lagged in performance and lifespan compared to red and green emitters.

Another key focus area is stability and longevity. New host–guest systems, where emissive dopants are embedded in stable host matrices, have significantly reduced material degradation under continuous operation. This has direct implications for the lifespan of OLED panels in televisions and smartphones.

Flexible and printable OLEDs are also gaining traction. Materials designed for solution processing and inkjet printing enable roll-to-roll fabrication, lowering manufacturing costs and opening the door to innovative applications like foldable phones, wearable devices, and even electronic textiles.

Finally, sustainability has become a guiding principle. Green chemistry approaches aim to synthesize OLED materials using environmentally friendly processes, reduce waste, and eliminate hazardous solvents. These strategies not only address regulatory pressures but also appeal to eco-conscious consumers.

In summary, OLED material science is advancing toward smarter, more efficient, and sustainable solutions—laying the foundation for the next generation of high-performance electronics.

Applications Powered by OLED Materials

OLED materials are revolutionizing the way we interact with light and visual technology, enabling a wide range of applications that combine beauty, efficiency, and performance. From consumer electronics to next-generation wearables, the versatility of OLEDs stems from the tunability and flexibility of their organic materials.

The most visible application is in consumer electronics, where OLED displays dominate high-end smartphones, televisions, and tablets. These devices benefit from OLEDs’ ability to produce self-emissive pixels, which eliminate the need for backlighting and allow for ultra-thin, high-contrast, and power-efficient screens. Deep blacks, vibrant colors, and wide viewing angles are now standard thanks to advanced OLED emitter materials.

In automotive and architectural lighting, OLED panels offer uniform, glare-free illumination with a soft, natural feel. Their slim profile, low heat generation, and aesthetic design potential make them ideal for interior lighting, dashboards, and taillights. OLED tail lamps, for instance, are already featured in premium vehicles from brands like Audi and BMW.

Wearable and flexible electronics are another frontier where OLED materials shine. Flexible and foldable OLEDs—enabled by mechanically compliant substrates and stretchable materials—are found in smartwatches, foldable phones, and experimental e-textiles. These applications demand materials that maintain performance under mechanical stress while consuming minimal power.

Emerging uses also include augmented and virtual reality (AR/VR) headsets, where lightweight, high-resolution, low-latency displays are essential. OLED microdisplays are currently leading the charge in delivering immersive, eye-friendly visuals in compact form factors.

OLED materials have even been explored in medical devices and bio-integrated sensors, owing to their compatibility with soft and biocompatible substrates. As the material science behind OLEDs evolves, we can expect further integration into smart surfaces, ambient lighting, and even transparent displays.

Challenges and the Future Outlook

While OLED technology has made significant strides in recent years, several challenges remain that impact the scalability, cost, and overall performance of OLED materials. One of the main hurdles is material degradation, particularly in blue OLEDs. Blue emitters historically suffer from shorter lifespans compared to red and green counterparts, limiting the longevity of OLED devices. Researchers are working on stabilizing blue OLED materials to enhance their durability and efficiency, which is crucial for the widespread adoption of OLEDs in long-lasting products like televisions and automotive displays.

Another ongoing challenge is manufacturing cost. Although OLED displays are increasingly found in consumer electronics, they are still relatively expensive to produce compared to traditional LCD displays. The complexity of OLED manufacturing processes, including the need for clean rooms and precise deposition techniques, adds to the cost. However, advancements in roll-to-roll printing and solution processing are gradually reducing these costs, making OLED technology more accessible for mass-market applications.

Energy efficiency remains a key area of improvement. Despite being more energy-efficient than conventional lighting technologies, OLEDs still face competition from technologies such as LED lighting, which can be more energy-efficient in certain applications. The development of more efficient TADF and hybrid emitters is helping to push the limits of OLED efficiency, making them increasingly viable for general lighting and other energy-sensitive applications.

Looking to the future, sustainability is becoming a critical focus. The OLED industry is moving toward greener materials and more environmentally friendly production processes. Research into recyclable OLEDs and materials that can be synthesized without harmful solvents or metals is gaining momentum. Furthermore, transparent OLED displays, which could serve in applications like windows and interactive surfaces, are under development and promise to revolutionize how we interact with our environment.

As OLED technology continues to mature, the industry is set to benefit from ongoing advances in materials science, sustainable practices, and innovative manufacturing techniques, which will enable more efficient, cost-effective, and environmentally friendly OLED products in the future.

References

Forrest, S. R. (2004). The path to ubiquitous and low-cost organic electronic appliances on plastic. Nature, 428(6986), 911–918.

https://www.nature.com/articles/nature02498

Reineke, S., Thomschke, M., Lüssem, B., & Leo, K. (2009). White organic light-emitting diodes: Status and perspective. Reviews of Modern Physics, 85(3), 1245–1293.

https://journals.aps.org/rmp/abstract/10.1103/RevModPhys.85.1245

Uoyama, H., Goushi, K., Shizu, K., Nomura, H., & Adachi, C. (2012). Highly efficient organic light-emitting diodes from delayed fluorescence. Nature, 492(7428), 234–238.

https://www.nature.com/articles/nature11687

Adachi, C. (2014). Third-generation organic electroluminescence materials. Japanese Journal of Applied Physics, 53(10), 100210.

https://iopscience.iop.org/article/10.7567/JJAP.53.060101/meta

Kaji, H., Suzuki, H., Fukushima, T., et al. (2015). Purely organic electroluminescent material realizing 100% conversion from electricity to light. Nature Communications, 6, 8476.